Centerless Polisher/Buffing Fixture | MSD-P-15

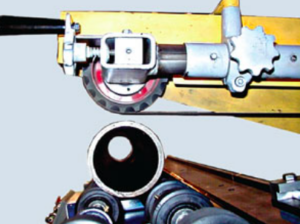

A sturdy 2” x 4” tubular frame (standard frame length is 15 ft.) consists of two sets of polyurethane rollers.

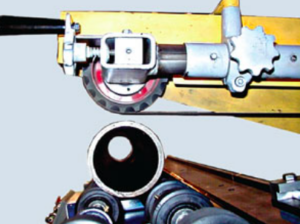

The polishing head is driven horizontally the length of the fixture by a vector A.C. drive. A rack and pinion drive system is used for smooth traversing of the carriage. The head is supported by four Teflon lined guides, which slide on aluminum support rails.

Our centerless polisher/buffer features a sturdy 2” x 4” tubular frame consists of two sets of polyurethane rollers. The gear motor drives one set, and the other set is easily adjusted to accommodate shafts from 1” to 14” OD.

MS-D’s centerless polisher uses a “G & P 72” abrasive belt polisher Model B372-3 as its polishing head. The head uses a 3” X 72” belt and is driven by a 3 HP 230/460 volt, 3 phase, 60 hz. motor.

We also make a 5 HP head with a 3” x 90” belt available to increase the time between belt changes. A larger horsepower head with a longer belt is available to increase productivity and increase the time between belt changes.

A vector A.C. drive runs the polishing head horizontally the length of the fixture. A rack and pinion drive system smoothly traverses the carriage. Four Teflon lined guides that slide on aluminum support rails support the head.

You can add a remote jog can to speed up set time or to manually polish and area.

As an option, we can offer these in a buffing wheel only or buffing wheel & belt combination.

- No need for centering or chucking rod in lathe. Faster setup time.

- For less set-up, you can hang the clevis can over end of fixture.

- High micro-finish.

- Use to check concentricity of shafts.

- You can position the belt polisher for specialty processes, i.e. angle grinding and chamfers.

Head can be tilted to grind chamfers or angled surfaces.

Clevis can be hung over end of machine for faster, easier setup. No machining required.

Levels repair welds on shafts. Head slides in and out to position wheel over rod for removing high spots.

Polyurethane Rollers

Gear motor drives one set of rollers.

Polishing Head

AC motor – Rack and pinion drive.

Teflon-lined guides and aluminum support rails.

Electrical Package

The centerless polisher’s electrical package allows automatic reversing of polishing head with time delays at the end of strokes. You may use this feature to remove chrome build-ups on re-plated shafts. Additionally, you can place the magnet stops to reverse the polishing head at the end of the rod being polished.

Stroke position limit switch and magnetic stop for stroke positioning.

A 5 HP head with a 3” x 90” belt is available to increase the time between belt changes.

Remote Cable | MSD-P-R

Manual Jog | MSD-P-MJ

We also make a 5 HP head (MSD-P-5HP) with a 3” x 90” belt available to increase the time between belt changes.

A 7.5hp (MSD-P-7HP) head with a 3” X 90” belt is available. This will speed up the removal process.

We can customize these polishing heads to fit any belt size.

Remote Control Station | MSD-P-RCS