Machinery Service & Design offers several additional tooling options.

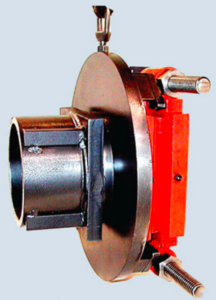

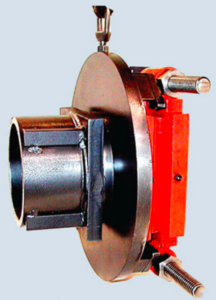

The MSD-AGT is used to secure cylinder head glands, tubes, and nuts from 5” (127mm) to 16-3/4” (425mm) in diameter. This tool comes with hardened vise jaws. It was designed to fit onto your existing MSD-ABT base plate. Base plate and L-Brackets are sold separately.

6” pilot holds the tool steady in the Nut Busters®.

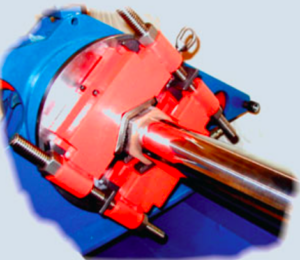

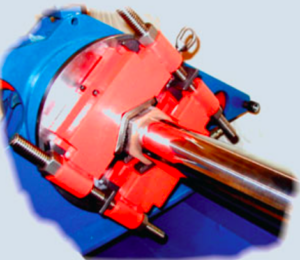

Adjustable tool typical installation in a Nut Buster. This tool has a 4-point contact on round surfaces and will not have the distortion problems that a pipe wrench would have.

Shown here on a hex nut.

Shown here is a typical setup to remove a nut that is not standard.

Lock Pin | MSD-LP

The MSD-LP lock pins are used to easily and quickly pin the slide plate in place to minimize movement during disassembly and assembly. They are sold in sets of two.

Lock pin inserted through slide plate and disassembly table.

Vacuum Pump System | MSD-VPS

The Machinery Service & Design vacuum system is used to assist the reassembly of hydraulic cylinders. This system takes advantage of atmospheric pressure to simplify the process of entering seals into the bore chamfer and retracting the shaft.

Our two-stage pump delivers high volume and produces vacuum up to 30” of mercury.